Whether you’re printing a simple handout for a tradeshow, a high impact direct mail piece, or posters for a new office space, the printing process is much more complex than people think. In fact, there are different types of printing to choose from based on the needs of the job. Our account team recently had the opportunity to tour some of our print vendor’s facilities, and we were reminded of everything that goes into the printing process, specifically for conventional/offset printing and digital printing. Here’s a quick overview of the two processes to help provide an understanding of what exactly goes on behind the curtain at a print facility:

Conventional/Offset Printing

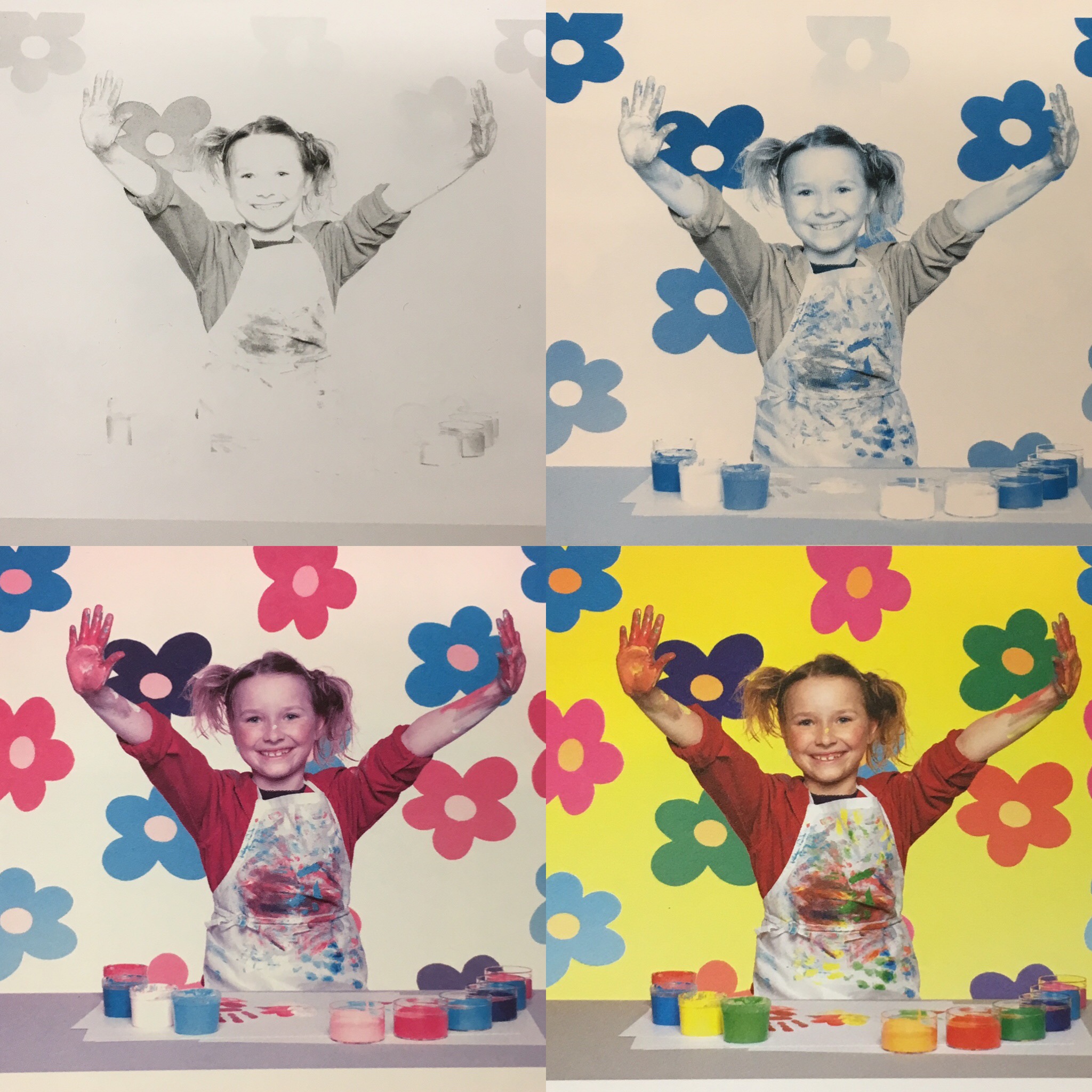

The conventional/offset process is much more “involved” than one would expect. To start, it is important that the design files are finalized and set up to reflect the CMYK color model, to match the ink used in the press machine. The machine stores the ink for each of the CMYK colors in separate plates and uses large rubber blankets to transfer the ink to the paper – imagine a massive rubber stamp with a surface area large enough to resemble a blanket, and that blanket rolls the ink on to a large sheet of paper. The colors are applied to the paper one at time, each filling the blank space with tiny dots, all which ultimately combine to match the CMYK colors used in the design file.

The conventional/offset process is much more “involved” than one would expect. To start, it is important that the design files are finalized and set up to reflect the CMYK color model, to match the ink used in the press machine. The machine stores the ink for each of the CMYK colors in separate plates and uses large rubber blankets to transfer the ink to the paper – imagine a massive rubber stamp with a surface area large enough to resemble a blanket, and that blanket rolls the ink on to a large sheet of paper. The colors are applied to the paper one at time, each filling the blank space with tiny dots, all which ultimately combine to match the CMYK colors used in the design file.

When reviewing printers’ proofs, you’ll notice that there is typically a grid of colors along the edge of the paper. When the proofs come off the press, this grid is run through a machine that determines the composition of the colors used in the proof. This helps the printer gauge how accurately the combination of CMYK colors on the proof match those used in the design file. It may take the press a few runs to match the CMYK colors used in the design, but once the composition of colors is accurate, you’ve got beautifully printed pieces with high quality color and images.

Because of the time involved in preparing the press for a print job and ensuring the proper color composition, the set-up cost yields a higher cost per piece than other printing methods. However, high quantities will lessen the burden of the set-up cost by distributing the cost across more pieces.

Digital Printing

With less steps required to set up a print job, the digital printing process is much simpler. For a digitally produced piece, a print press applies the colors used in the design to the paper all at once, eliminating the need to set up different colors on separate plates. Digital printing is ideal for short runs of a product, because the lower set-up costs are more quickly absorbed into the total project cost, and the turn-around time is much faster. However, while the final product is still high quality, the imagery will be less crisp than if it were printed with an offset printer. This is why we recommend digital printing for projects where our clients are creating samples or prototypes of a product – for instance, when you’re attending an event like a tradeshow. When you only need a handful of samples, digital printing is the way to go because your costs will be lower and you can get feedback on your designs and messaging before you spend a significant amount of your budget on a full run.

At the end of the day, both processes result in quality printed pieces. What it comes down to are the needs of the print job. We like to consider the following when selecting between offset and digital printing:

- What quantity do you need printed?

- Are you on a tight schedule?

- What’s your budget?

- Are there intricate details within the images used in the design?

With two great options to choose from for your next print job, the only thing known for certain is that finalizing a design and sending it off to the printer is just the beginning.